AVTEC’s success is attributable to a strong focus on in-house research and product development capabilities.

AVTEC has a centralized tech center at Hosur; development facilities at both Hosur and Pithampur along with a design house in Switzerland.

Both Indian centers were built to upgrade the current product range and design new products for a growing range of applications.

AVTEC’s core strength lies in technology absorption, seamless integration of product design, prototype building, testing and validation. The company offers a full range of solutions for Powertrains ( i.e., engine and transmission systems) and components – from product concept, design , prototyping , testing , validation and manufacturing. AVTEC’s Swiss subsidiary ASSAG, is a leading enterprise in drive system and face gear technology. ASSAG is known for its innovative solution in the field of face gear differential drives, high precision gears and is pioneer in face gear technology with several patents to its credit.

CAD

FEA

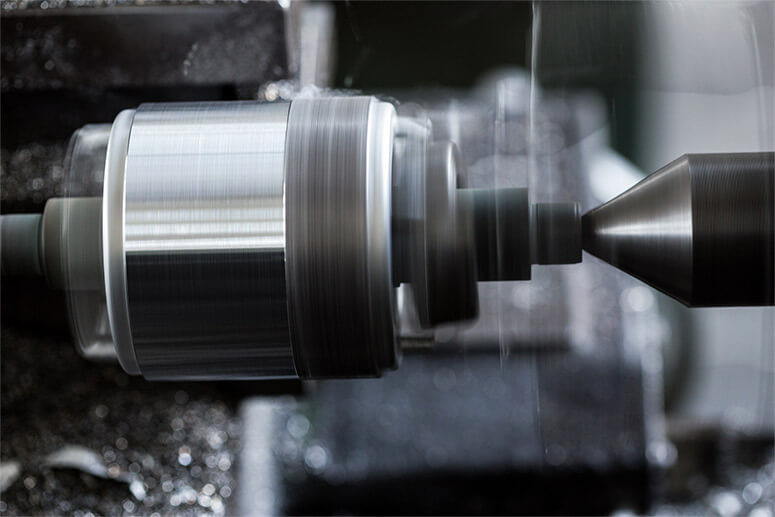

Gear train

Gear Box

AVTEC firmly believes in a culture of continuous improvement & evolution as it’s prime growth drivers. With an aim to do the things right, “first time–every time” and keeping pace with the rising & shifting Customer requirement, Company has swiftly adapted to Lean Manufacturing, TPM, MOST tools to enhance it’s Manufacturing capabilities. Quality of design and Quality of Conformance being the fundamental principles driving manufacturing processes to deliver reliable products.

With a strong emphasis on employee involvement to sustain Quality, company engages renowned world-class consultants to train it’s human resources to enhance their skills and focus on in Process validations / controls for Quality outputs. All manufacturing facilities are TS 16949 certified for Quality Management Systems by DQS. The company has also received a Quality Excellence Status award from Caterpillar, and the Q1 Quality Status award from Ford India. AVTEC also has a product validation facility. Our quality agenda is bolstered by global technical partnerships and business collaborations forged with OEMs such as Peugeot Citroen Moteurs, Caterpillar and Daimler.

Heat Treatment Processes

Sealed Quench furnace with CQI 9 for Case carburizing & carbo-nitriding

Gas Nitriding Furnace – Horizontal & Pit type

Induction Hardening M/C & Plug Quench

Allied Equipment: Shot blasting, shot peening, tumbling

Key Processes

Normalizing

Stress Relieving

Hardening & Tempering

Case Hardening- Case Depth:0.5-2mm

Carbo - Nitriding- 0.4mm-0.7mm

Carbo-Annealing -1mm-2mm

Gas Nitriding- Case Depth:0.2-0.45mm

Induction Hardening-Shafts Case Depth: up to 4mm

Plug Quench of slender components (Hardening)

De-Scaling (Tumbling) & De-Burring of clutch plates & Pump Gears

Metrology

CMM- Carl Zeiss, Brown Sharpe & LK

Gear Involute Tester- Klingelnberg & Wenzel

Surface Analyzer- Kosaka

Portable Surface Analyzer- Mitutoyo

Cam Profile Tester- Trimos

Roundness Tester – Taylor Hobson

Metallurgy

Microscope with Image Analyzer- Carl Zeiss

Universal Testing Machine- 1& 16 Tons

Rockwell & Rockwell Twin Hardness Tester

Macro & Micro Vickers

Millipore Washing & Filtration Kit

Residual Stress analyzer

Magnetic Particle Inspection

Clean Room Setup

Sign up with us